All About Electric School Bus Repowers

Repowering fossil fuel-burning school buses to run electric is an innovative approach to help fleets electrify today and complement new vehicle purchases.

Image credit: SEA Electric

Repowered electric school buses can play an important role in the electric school bus transition. With lower upfront costs and zero tailpipe emissions, repowers can help school districts and private fleet operators bring clean rides to more students nationwide – all while contributing to a more sustainable circular economy. As of May 2024, repowered school buses have seen deployment in California, Illinois, and New York, with orders now placed by school districts in Massachusetts and Oregon.

But what are repowers, how do they work, and what should school bus fleet operators and policymakers know about this electrification technology? Learn more below!

Jump to a question:

· What is an electric repower?

· Why consider an electric school bus conversion?

· How do repowers compare to new electric school bus manufacturing?

· What companies are repowering electric school buses today?

· Which school buses are the best candidates for repowering?

· What funding is available to purchase electric school bus repowers?

· What laws and regulations apply to electric conversions?

· I’m interested in incorporating repowers into my fleet. Where should I start?

What is an electric repower?

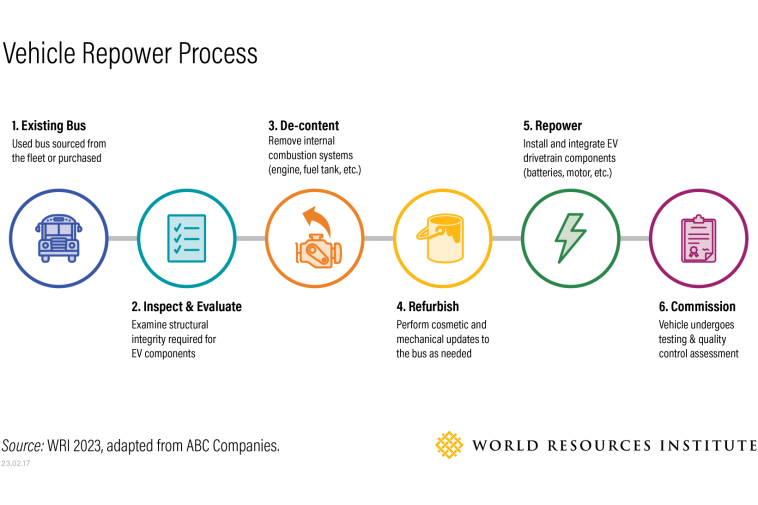

An electric repower — sometimes referred to as an electric conversion or retrofit — involves the removal of a vehicle’s internal combustion engine that burns a fossil fuel like diesel, gasoline, propane, or natural gas and replacing it with an electric drive system, transforming the vehicle to one that is fully battery-electric with no tailpipe emissions. This conversion process can be accomplished with a variety of types of vehicles, including school buses!

Why consider an electric school bus conversion?

- Lower upfront purchase cost. Today the average upfront purchase price of a new Type C electric school bus is about $395,000. While the lower fuel and maintenance costs of an electric school bus can result in a lower total cost of ownership, the upfront price tag remains a barrier for many operators. This high cost disproportionately impacts historically underserved communities who may have fewer resources for electrification. Comparatively, a Type C repower costs between $100,000 to $200,000, making them more cost competitive with fossil fuel-burning options. For a more comprehensive comparison, check out our TCO analysis between three school buses: an electric repower, a new diesel, and a new electric.

- Meet local electrification requirements. As of May 2024, 29% of U.S. school bus riders and 35% of the school bus fleet fall under an electrification transition goal or requirement. Repowering can help reach these state and local targets by lowering the cost to electrify, supporting accelerated fleet turnover. Boston, for example, intends to electrify all 700+ of its school buses by 2030. In New York, a state-wide requirement calls for 100% zero-emission school bus sales by 2027, and a 100% zero-emission fleet by 2035. With this, New York is entering an opportune repower window, where a diesel-burning school bus purchased in 2024 to 2026 can only operate for nine to 11 years, but a fleet operator can repower that bus to run electric before 2035, extending its useful life. To support this, repowers are eligible for the $500 million New York School Bus Incentive Program.

- More school bus options. As the electric school bus market grows, we expect to see a wide variety of bus types and options available. However, most new electric school bus models are currently only offered in one or two wheelbase options. Fortunately for operators that require a specific wheelbase not yet offered, repowering offers a path forward to take vehicles already within the fleet with those specs and convert them to battery-electric.

- Upgrade school buses with aging drivetrains. It is not uncommon to replace a combustion engine or transmission partway through a school bus’s life because drivetrain components tend to age faster than the body and chassis. Instead, fleets can consider an electric conversion, especially if fleet transition requirements align with a drivetrain overhaul. This can lengthen the school bus’s usable life, reduce TCO and provide students with a clean ride to school.

- Support a circular economy. A repower reuses an existing school bus’s body and chassis. Compared to a new electric school bus, a repower requires fewer raw materials and emissions to manufacture. At scale, repowers could reuse thousands of tons of steel, aluminum, glass and other materials. In addition, if a diesel-burning school bus is repowered rather than sold, it can prevent that vehicle from continuing to pollute in another state or country, as long as the engine is scrapped during the repower process.

How do repowers compare to new electric school bus manufacturing?

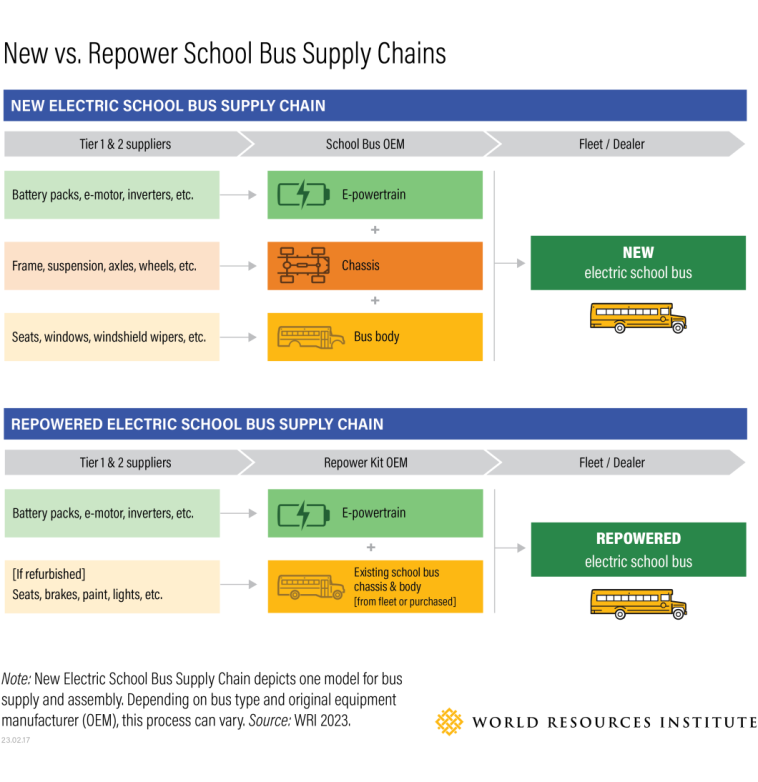

New and repowered electric school buses are similar vehicles and are built using comparable electric drive system components. In many cases, these components are sourced from the same suppliers. The key difference is that for a repower, the electric drive system is installed in an existing school bus rather than in a new school bus body and chassis.

Today, the repower process is quite common in the new school bus market. As of 2023, more than 50% of electric Type A school bus models available are new-vehicle repowers, including from brands like Micro Bird and Thomas Built. These school buses are built using a brand-new combustion engine cutaway chassis from Ford or General Motors, where the combustion system is removed and an electric drive system is installed — all of which occurs before the school bus goes into service.

The most complex part of a school bus conversion is ensuring the new electric powertrain system seamlessly integrates with existing systems in the school bus chassis and body, such as the wiring harness, dashboard instrument cluster, stop sign arm, and others.

Depending on the condition of the school bus being converted, the interior and exterior of the vehicle may also be refurbished. The refurbishment process can include reupholstering seats, adding a new coat of paint or removing rust underneath the school bus. A vehicle just out of warranty can need little to no work, while a ten-year-old school bus may need a few thousand dollars put into it. Repower companies usually do not perform refurbishment, it is usually done in-house by the operator or contracted out to a dealer.

What companies are repowering electric school buses today?

As of May 2024, seven companies in the U.S. offer electric conversions for school buses. Some are focused on specific school bus types. Like new school bus manufactures, some repower companies conduct conversions at a central, designated facility. Others are using a more distributed model, partnering with an existing network of dealers or conversion specialists, trained to install the electric repower system.

For a table of company profiles, see number six in 8 Things to Know about Electric School Bus Repowers. For more information on selecting a vendor, see the Department of Energy’s Guide on Repowers.

At scale, repowers could sustainably reuse thousands of tons of steel, aluminum, glass and other materials, reducing the amount of raw materials needed to manufacture electric school buses.

Which school buses are the best candidates for repowering?

It’s important to give careful consideration to which school buses in your fleet may be good options for repowering. Some key considerations include:

- Manufacturer familiarity and preference: Repower companies often prefer to focus on school buses from a specific original equipment manufacturer (OEM), produced within a range of model years to efficiently convert school buses with similar specifications. Repowering a school bus that the company is not familiar with can increase the time and cost, especially if that make/model has not been converted previously. Some companies convert only Type A or C school buses, while others focus on a range.

- School bus age and condition: Overall, a school bus’s condition is a function of its age and where it operates. For instance, school buses running routes in colder climates with more corrosive conditions will show signs of rust sooner. Logan Bus Company, which operates five repowered Type C electric school buses in New York, opted to convert 10-year-old diesel-burning school buses. While Logan Bus expects the vehicles run another 10-12 years on the new electric drivetrain, for future conversions, they intend to convert younger school buses that recently exited their warranty period to reduce refurbishment costs, which were around $10,000 per school bus for the repowers currently in their fleet. For more information on school bus age considerations, see number seven in 8 Things to Know about ESB Repowers.

- Fleet composition: One-off repower projects will be more costly on a per-school-bus-basis than an order for several repowered school buses. You can help reduce the cost per unit to repower by selecting a make/model of school bus that you have several of in your fleet. Additionally, if a fleet does not already own a school bus that can be converted, a used school bus may need to be purchased for the conversion. This can add to the upfront cost of project, detailed in our Repower TCO Comparison.

- Timing up repairs and upgrades: If portions of the fleet are already scheduled for engine replacement, CNG tank replacement, or cosmetic refurbishment, these vehicles could be good candidates for repowering.

- Fleet flexibility and downtime: If a fleet does not have spare school buses, it is important to ensure vehicles selected for repowering can be out of service for a designated period of time to conduct the conversion (and potential refurbishment). Conversion companies advertise the ability to complete repowers within a matter of weeks, which can align with mid-year breaks or the summer months.

- Funding program requirements: Some funding programs have an age requirement for the diesel-burning buses to be eligible for replacement. For example, in Texas’s All Electric program, only vehicles model year 2009 and older are eligible (for repower companies, 15+ year old buses are not top candidates to convert).

What funding is available to purchase electric school bus repowers?

Electric school bus repowers often have lower upfront purchase prices, and available federal and state funding can help lower costs even further.

Federal funding programs

There are two programs at the federal level that can provide funding for electric school bus repowers:

- Diesel Emission Reduction Act (DERA): Under DERA, vehicle conversions to battery-electric classified as a “Certified Engine Replacement.” Eligible replacement electric drivetrain systems include only those certified by EPA and/or the California Air Resources Board (CARB). Repower manufacturers should ensure their conversion system is certified to take advantage of this program.

- Commercial Clean Vehicle Credit: provides a tax credit of up to $40,000 to cover the incremental cost of purchasing electric vehicles weighing over 14,000 lbs. The program is administered by the Internal Revenue Service (IRS) and tax-exempt entities, including school districts, are eligible for the credit. Repower companies should ensure they are a Qualified Manufacturer.

State Funding Programs

The majority of funding opportunities for electric repowers are available at the state level. The map below details repower-eligible funding programs by state. California, Colorado, Minnesota and New York have established sizeable electric school bus funding programs that include repowers as an eligible vehicle category. Some of programs listed here are state-administered DERA funds, which follow the federal DERA program guidelines.

What laws and regulations apply to electric conversions?

School buses are subject to regulations at the federal, state and sometimes local levels designed to ensure safety. Each state — and some cities or school districts — has its own unique set of minimum school bus standards and specifications. Any school bus selected for conversion to electric should already meet the safety regulations present in the location it has been operating in. There are a handful of factors to consider to ensure buses meet local specifications.

- Inspection: Before going into service, the vehicle will likely need to undergo inspection and approval. For example, in New York City, a school bus converted to electric must undergo inspection before transporting students — just like all new school buses. This includes an inspection by the New York State Department of Transportation, followed by one from the NYC Department of Education.

- Bus age limits: Some states and school districts limit the age of school buses used for student transportation, often defined by a maximum vehicle age or fleet average. In New Jersey, for instance, some school buses can only be used for student transportation for 12 years from the date of manufacture. If a repowered school bus retains its vehicle identification number (VIN), its age is linked to its original manufacture date – not the date of conversion – which may limit how many years it can continue to operate at certain location.

- Operating in a new state: If the school bus being converted is sourced from outside the fleet and previously operated in a different state, the bus may require updates to meet specifications of the new state it will operate in.

- New bus requirements: Older school buses may or may not meet or be subject to newer state specifications enacted after a bus was built. For example, various laws requiring seatbelts in school buses exist in California, Florida, Louisiana, New Jersey, New York and Texas. If converting an older school bus model, it’s important to check if it is subject to newer regulations.

I’m interested in incorporating repowers into my fleet. Where should I start?

If you’re ready to start:

- Determine which school buses from your fleet could be good candidates for repowering. Available repower models and preferred school bus models to convert can be found in the Electric School Bus U.S. Buyer’s Guide.

- Assess how a combination of new and repowered vehicles can help you meet fleet goals. It may be that the oldest vehicles in your fleet are best-suited to be replaced by new school buses, and younger vehicles — such as those that have recently exited their warranty period — are best-positioned for repowering. Repower companies generally prefer to convert buses no more than 10-years-old.

- Look to see if there is state or federal funding available. Start by checking the funding map above.

- Draft and publish a request for proposal (RFP) to gauge what options exist. Like all school bus purchases, consider the inclusion of tools like Service Level Agreements to ensure vehicle uptime.

- Select a repower vendor that best fits your fleet makeup, duty cycle and aligns with existing funding opportunities.

Have questions? Schedule a call with the Electric School Bus Initiative team.

Continue learning about repowers

The Electric School Bus Initiative is building a collection of resources on electric school bus repowers:

- 8 Things to Know about Electric School Bus Repowers

- Repowering the Transition to Electric in New York and Lowering Total Cost of Ownership

The U.S. Department of Energy Alternative Fuels Data Center has also published information on this topic: