How to Ensure a Sustainable Future for Electric School Bus Batteries

Support from the U.S. Environmental Protection Agency’s $5 billion Clean School Bus Program in 2022 led to electric school bus purchases in every state in the nation and has put significant momentum behind electric school bus adoption nationwide. However, batteries from the buses purchased in that first year of the program will, by about 2030 or so, be at the end of their warranty and their useful life in the vehicle.*

While the challenges posed by mineral extraction for electric vehicle batteries are well understood, less attention has been paid to battery end-of-life management. If retired school bus batteries end up in landfills, the potential for toxic leaching and fires could pose environmental and health risks to neighboring communities. On the other hand, recycling and second-life use options — such as providing battery storage for renewable power sources — could bring significant equity, resiliency and economic benefits.

Given the widespread adoption of electric school buses spurred by the Clean School Bus Program and other efforts, this sector is poised to serve as a model for other medium- and heavy-duty vehicle types that will be arriving at a similar decision point in the coming years.

Here, we highlight opportunities and barriers of battery repurposing and recycling so that school districts, vehicle manufacturers and policymakers can set a foundation to build a circular value chain — and sustainably manage 480,000 batteries from a fully electrified U.S. school bus fleet.

Options for Electric School Bus Batteries at the End of Their Useful Life

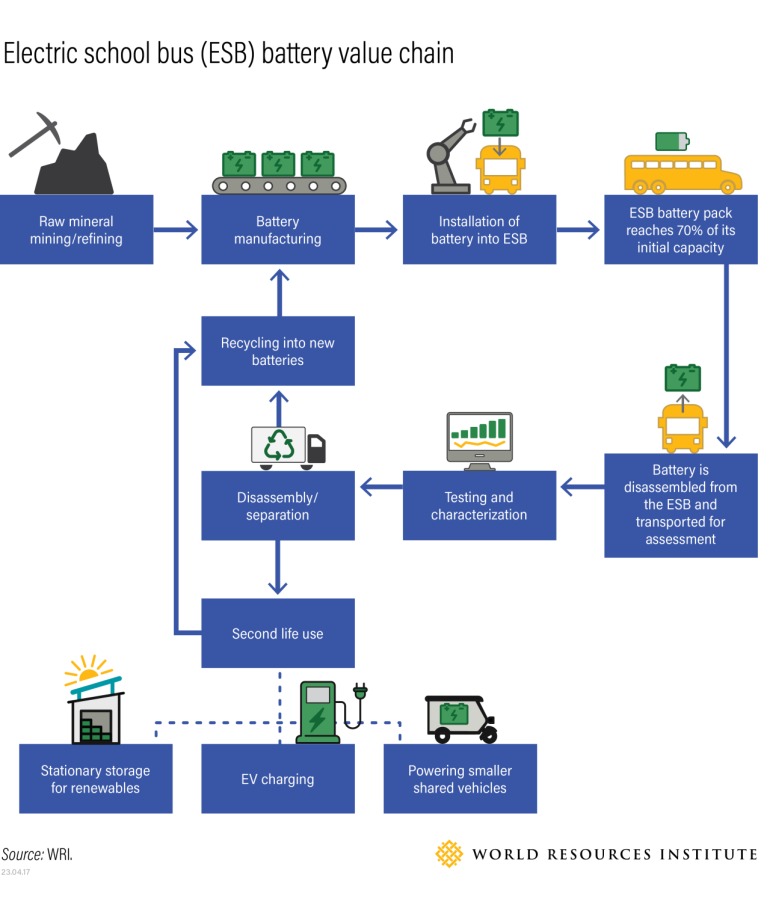

Over time, the capacity of an EV battery diminishes. Vehicle manufacturers expect electric school bus batteries’ capacity to drop to 70% within eight years, after which the battery is no longer deemed fit for the vehicle and must be replaced. (Batteries are replaced by the manufacturer at no cost to the bus owner within the warranty period.)

Once an EV battery reaches its end of useful life in the vehicle, there are three main pathways it can take: second-life use, recycling or disposal in a landfill or waste management facility. Other processes such as refurbishing, remanufacturing and repowering of EV batteries are not covered in this article.

Making recycling economically viable is the end goal to help reduce demand for newly extracted minerals and achieve a truly circular battery value chain. However, until recycling is feasible at scale — and because batteries still have storage capacity when replaced — ensuring a second life for electric school bus and other EV batteries is an important near-term approach that can help reduce the impacts of landfilling and mineral extraction. Landfill disposal is the least desirable outcome.

Battery recycling

Most electric school buses use lithium-iron-phosphate (LFP) batteries due to their low cost, ability for fast charging, range and thermal stability (a small number still use nickel-manganese-cobalt, or NMC, batteries). However, there are significant risks associated with extracting the critical minerals that go into these battery cells, including adverse impacts to the environment and nearby communities. Indigenous communities are particularly at risk: In the U.S., 79% of lithium reserves are located within 35 miles of Indigenous reservations, increasing up to 89% for copper and 97% for nickel.

When electric vehicle batteries are recycled, the materials recovered can be used to manufacture next-generation batteries, with some battery recycling processes claiming up to 95% recovery of critical minerals. This results in fewer emissions than if the materials were mined and can positively impact communities by reducing the need for new mines. The current EV battery recycling process mainly uses scrap from production, as few EVs existed 8-10 years ago. The feed for lithium-ion battery recycling has so far been limited to consumer electronics; however, this is expected to change rapidly as more EV batteries reach the end of their useful life.

To meet demand for domestic battery materials and recycling capacity, U.S. federal agencies are taking a whole-of-government approach:

- Department of Energy is investing in battery recycling companies like Redwood and Li-Cycle, in addition to a portfolio of RD&D projects to increase capacity and innovation.

- Department of Energy is supporting ReCell Center, a consortium of national labs and universities which aims to grow a sustainable advanced battery recycling industry by developing economic and environmentally sound recycling processes.

- To help spur a marketplace, the U.S. Senate recently passed a bill that mandates EV battery repurposing and recycling for roughly 645,000 federal fleet vehicles, when fully electrified.

- Domestic content requirements for battery materials, as outlined in the Inflation Reduction Act, and energy security concerns both incentivize battery recycling.

While these and other initiatives have put momentum behind battery recycling, there are some challenges that still need to be overcome in the near term.

First, battery recycling today is an energy-intensive industrial process that requires significant heat and water resources and causes greenhouse gas emissions. While these impacts are much lesser than mining, they could harm historically disadvantaged communities located near recycling facilities.

Second, the unfavorable economics of electric school bus battery recycling may act as a deterrent for fleet owners. The low price of recycled LFP batteries (which is sensitive to commodity prices of lithium, as these batteries don’t contain high-value cobalt or nickel) can reduce the economic viability of recycling most electric school bus batteries using current commercially viable processes. In addition, there is the high cost of packaging and transporting hazardous waste like used EV batteries, which can make up nearly 60% of the cost of recycling.

Second-life use or repurposing

Although recycling is a critical piece of developing a circular battery value chain, it is currently constrained by technological innovation, governance and economics. Luckily, EV batteries can be used for other applications in their “second life" prior to recycling.

Second-life or repurposed EV batteries can be valuable community assets that help provide resiliency and clean electricity affordably. An electric school bus battery with less than 70% of its power, while no longer fit for the vehicle, could still serve other, less demanding, purposes. Because the battery pack still possesses most of its original capacity, it can be used for applications like on-site storage for solar energy and electric vehicle charging for an estimated 7-10 additional years.

Such opportunities not only keep EV batteries away from landfills but also lower demand for mineral extraction to create additional batteries; this can help reduce the associated burdens on disadvantaged and Indigenous communities.

Electric vehicle batteries, including those from electric school buses, can be repurposed for a variety of applications after their useful life including:

- Application in stationary storage: Battery modules sourced from various electric vehicles can be aggregated to create on-site stationary storage or microgrid solutions. These can be used by grid operators as utility-scale storage or by property owners to power buildings — such as school bus depots or school buildings using intermittent renewable energy sources like solar. Such solutions can also offer community resilience benefits (during local power outages, for example) and improve energy access.

- Application in EV charging: For fleet depots that need fast charging capabilities for mid-shift recharging or fast turnaround of vehicles for the next use, local energy storage can provide a power boost to fast chargers. This can eliminate short-term spikes in demand through peak-shaving to reduce energy costs. For sites supplied with lower voltage, local energy storage can help provide a combined higher voltage to enable faster charging. School districts considering fast charging could use this strategy to improve cost planning and limit expensive infrastructure upgrades. For example, Electrify America has partnered with Volkswagen to repurpose their used vehicle batteries in charging stations.

- Application in vehicles and appliances with lesser demand: Smaller shared vehicles or appliances have lower capacity demands from their batteries. This provides a good opportunity to reuse vehicle batteries for such purposes. For example, batteries used in Audi e-tron cars will be repurposed to power 3W autorickshaws in India.

Based on current electric school bus adoption trends, WRI estimates that about 2.82 gigawatt-hours (GWh) of battery capacity could be available for repurposing after 2030 — enough to power 270 homes for a year. A full transition of the U.S. school bus fleet to electric would offer 87.31 GWh for repurposing, or enough capacity to power over 8,200 homes for a year.

A few key challenges must be overcome to make second-life use or repurposing of EV batteries viable at scale.

One key barrier to repurposing (and recycling) used EV batteries is the lack of a clear chain of custody. Once an electric school bus battery is retired from the vehicle, there may not be an identified stakeholder responsible for it. Currently, electric school bus and battery manufacturers are not required to determine a plan for the battery at the end of its useful life. Even if a vehicle or battery manufacturer does have a public plan for repurposing and recycling the battery, but they don’t own the battery in the bus, their influence ends at the point of sale. This can leave a gap in battery ownership, risking its disposal in a landfill.

In addition, lack of access to data about crucial battery characteristics across stakeholders in the value chain makes it challenging for dismantlers, energy storage companies and recyclers to understand if a battery is in a suitable condition for repurposing. Battery manufacturing can be a competitive differentiator among automakers, causing data across the industry to remain siloed. However, a standardized battery label with a digitally accessible log (for example, a Battery Passport) could share non-proprietary or anonymized data regarding design and status, such as battery state of health, with markets and customers. This would substantially improve transparency.

The Global Battery Alliance, an international collaboration platform to help establish a sustainable battery value chain by 2030, is leading pilot projects with several automakers to ensure tools like Battery Passport can be implemented at scale. Closer to home, California Air Resources Board’s (CARB) Advanced Clean Car Rule II regulation will require battery labeling starting in 2026.

Depending on the second-life application of a retired EV battery, there are also cost-related issues with permitting, certifications, transportation of used batteries, and testing to ensure the battery can be repurposed. More research is needed to determine which entity bears these costs and at which stage of the process.

Resolving other emerging issues, such as clarity on second-life use warranties, federal disposition rules and incentives for battery repurposing, will be important as more EV batteries reach end-of-life.

Landfill disposal

If EV batteries are not repurposed for second-life use or recycled, they may end up in a landfill. Landfill disposal is an undesirable outcome, as battery cells can cause waste fires and release hazardous toxics into the environment, including heavy metals leaching into the soil and waterways. This can greatly increase the risk of acute and chronic toxicity, liver, kidney and intestinal damage, anemia and cancer in neighboring populations. Historically, landfill disposal typically takes place near low-income and underserved communities or in the Global South, which is a significant environmental justice issue.

Due to gaps in policy and regulation, lack of accessible market solutions and inadequate public education about end-of-life EV battery uses, some electric vehicle batteries could end up in landfills. But the trend is toward greater repurposing and recycling of these batteries, which can help reduce the adverse impacts of landfilling.

To this end, it is important to establish a clear chain of custody for electric school bus batteries after their useful life in the vehicle and to expand repurposing and recycling programs. Additionally, educating consumers about the importance of battery repurposing and recycling, using digital identifiers like Battery Passport to improve traceability, and providing convenient access to necessary infrastructure (such as affordable battery testing centers) can help reduce the likelihood of batteries ending up in landfills.

Equity Considerations for Closed-loop EV Battery Management

As electric school bus batteries reach the end of their useful life, repurposing can offer a sustainable and cost-effective way to extend their use. However, there are important equity considerations when it comes to EV battery repurposing and recycling:

- Environmental justice: Communities that are disproportionately impacted by pollution and environmental degradation should not be further burdened by the disposal of EV batteries. Recycling facilities should be located in areas that are not already overburdened by environmental hazards such as emissions from industrial processes, a depleted or polluted water table, or air pollution from freight activity. These facilities should have to consult with nearby and affected communities before beginning construction. Where facilities are proposed on or near Indigenous peoples’ land, their right to free, prior and informed consent should be respected.

- Access to facilities: Repurposing and recycling facilities should be easily accessible to all communities, particularly those that are low-income and underserved and may be located in remote areas. This can help alleviate the cost burden of transporting used batteries to facilities located far away.

- Economic opportunities: The repurposing and recycling industry can provide jobs and economic opportunities, particularly in communities that have been historically disenfranchised. This needs to be balanced with the environmental justice issue noted above through free, prior and informed consent of these communities. Companies that engage in such areas should prioritize a just and equitable transition by offering local opportunities such as job training, internships and high-quality employment. The Justice40’s Climate and Economic Justice Screening Tool can identify disadvantaged areas to help prioritize investments.

- Health and safety: Repurposing and recycling should be done in a way that is safe and minimizes risks to workers and surrounding communities. This includes ensuring that workers are trained and equipped with the necessary protective equipment and that facilities are located away from residential areas.

- Transparency: The process of EV battery repurposing and recycling should be transparent, with clear information provided about the environmental and social impacts of the process. This includes disclosing any potential hazards associated with the process and providing information about how the recycled materials will be used.

- Consumer awareness: School districts and vehicle manufacturers should be informed about the importance of repurposing and recycling their electric school bus batteries and the impact that their actions can have on the environment and society. This can be achieved through public education campaigns and clear labeling on EV batteries.

Overall, equity and environmental justice considerations should be central to the development of EV battery repurposing and recycling programs. This can help ensure that the benefits of this technology are distributed fairly across all communities.

Next Steps to Ensure a Sustainable Second Life for Electric School Bus Batteries

As we move towards electrification at scale, school districts, vehicle manufacturers and policymakers should collaborate to build the foundation for a second-life marketplace for electric school bus batteries. This will be an important step toward a more robust circular economy and pave the way for other sectors as they begin electrifying medium- and heavy-duty vehicle fleets. We recommend these actions:

School districts

While it is still early days for the electric school bus transition and for batteries going into repurposed applications, battery end-of-life planning needs to begin now. School districts should have a clear understanding of the value that resides in a battery after its useful life and a roadmap in place for sustainable battery management.

- For school districts that own the bus and the battery, there will be a cost for battery disassembly, packaging, transporting and testing. This needs to be accounted for in total cost of ownership models. School districts should consider requiring a battery management plan at end of useful life in the vehicle as part of their initial electric school bus RFP process and in assessing cost implications.

- School districts that plan to own the bus but not the battery should negotiate with their financing partner a discount relative to fair market value for reusing the battery for on-site storage or charging at the school district itself.

- For school districts that plan to set up stationary storage solutions at their buildings or depots, it could be economically beneficial to consider installing second-life EV batteries from their own vehicles. Those doing so should also share their experience broadly with other school districts to encourage participation.

Federal and state policymakers

For future federal or state funding opportunities, policymakers can:

- Ask funding applicants to provide a battery second-life or recycling plan and to identify potential owners for the battery after its use in the vehicle. In the absence of a clear owner, it is worth considering policy measures like Extended Producer Responsibility (EPR) to collect vehicle batteries as recommended by CalEPA’s Battery Recycling Advisory Committee. EPA could also invite applicants to opt into education and outreach on battery repurposing at future dates.

- Test a Battery Passport program and standardize labeling practices to enable transparency and make it easier to repurpose batteries. For example, the European Union’s Circular Economy Action Plan states that in the new regulatory framework for batteries, “transparency requirements will be considered, taking into account the carbon footprint of battery manufacturing, the ethical sourcing of raw materials and the security of supply in order to facilitate reuse, repurposing and recycling of batteries.”

- Stipulate that vehicles will not be eligible for funding unless manufacturers provide a certificate of producer responsibility or guarantee they will take back the battery at end of life if the bus operator does not want it. This could catalyze the battery second-life and recycling market and invite greater private sector participation.

- Partner with the Department of Transportation, Department of Energy and/or Joint Office of Energy and Transportation to conduct demonstrations of battery repurposing from electric school buses. This can help build the evidence necessary to create and scale these programs.

Electric school bus vehicle or battery manufacturers

Vehicle and battery manufacturers not only have a responsibility to manage EV batteries after their useful life, but also a great opportunity to build a new revenue stream in doing so. To realize this potential, automakers should:

- Declare a commitment to battery circularity. Taken as an industry, electric school bus manufacturers can send a strong market signal and spur partnerships with logistics companies, dismantlers, battery testing companies and recyclers. This could include voluntarily establishing an extended producer responsibility program and intentionally designing for disassembly.

- Use electric school bus batteries in second-life use applications to explore viability. This can involve building partnerships with utilities, EV charging companies and others who may repurpose these batteries and sharing valuable data with the industry to identify best practices.

- Ensure compliance with certification requirements that enable vehicle batteries to be repurposed, such as UL1974, and communicate this widely in order to improve confidence in utility-based applications for repurposed batteries.

- Partner across the industry to establish standardized labeling that provides non-proprietary transparent information to enable second-life use and recycling activities.

- Build public awareness and education on the benefits of repurposing and recycling batteries after their useful life in the vehicle, such as through educational materials, community town halls and helping shape consumer behaviors.

Some businesses are already leveraging the second-life value of electric school bus batteries, including utility programs such as Dominion Energy’s ownership of batteries in Fairfax, Virginia and Duke Energy’s partnership with Cherokee Central Schools (CCS) in North Carolina. Likewise, we could see turn-key asset management contractors of electric school buses, such as Highland or Levo, finding value in the extended use of vehicle batteries — much like Zenobe’s role with National Express’ e-bus fleet in the UK.

While there is a long way to go to ensure that electric school bus batteries hitting the road today are fully integrated into a circular system, school districts, policymakers and manufacturers can take action now to shape a sustainable future for these and all EV batteries.

*Based on warranties from vehicle manufacturers, we assume the useful life of the battery in an electric school bus to be eight years.